Corrosion Resistance

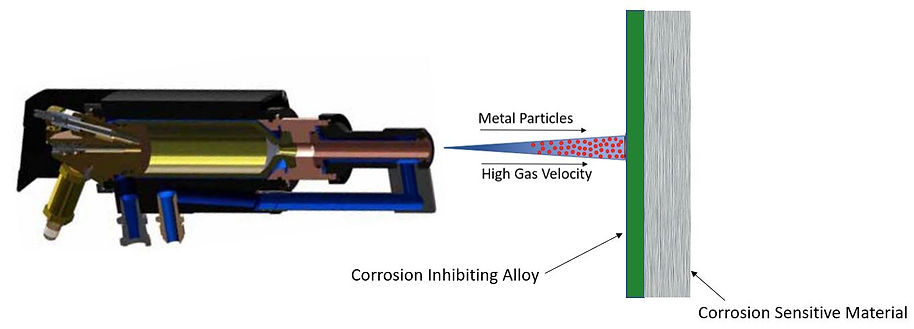

How it Works

Corrosion sensitive materials can be coated with non-sensitive alloys to prevent erosion of the base material.

Corrosion Resistant Material Thickens up to .250" Thick based on physical geometry and base metal

The additive material provides a layer of protection to be base alloy, allowing for extended life in the corrosive environment.

Corrosion Resistant Alloy Stadard Options

Stainless Steel Alloys

Nickel 200

Nickel Super Alloys (Inconel/Hastelloy)

Various Carbides

Case Study

Problem Statement: 316SS Tank Agitator Shaft was being corroded/dissolved in less than 12months by harsh chemical

Solution: Spray coat shaft with a chrome carbide alloy, covering all surfaces

Result: Over +5X service life out of product while preventing process down time

A customer uses a very harsh chemical to manufacture their automotive product. The chemical is so harsh it would 'eat' or corrode away a 4.00"Dia 316 Stainless Steel mixing shaft 7ft long in less than 12months. On the 12month service interval, the shaft would be pulled out of tank and shown to be basically a 'toothpick'. In an effort to improve their process performance they asked us to spray a corrosion resistant alloy on the shaft to experiment and find out if the spray coating would improve the equipment life and function in their process.

After their last service interval, 5yrs later, the agitator shaft looks the same as new, with zero corrosion.

The spray coating saved our customer the cost of the new mixing shafts and allowed their process to be at full capacity through the 12month service interval.